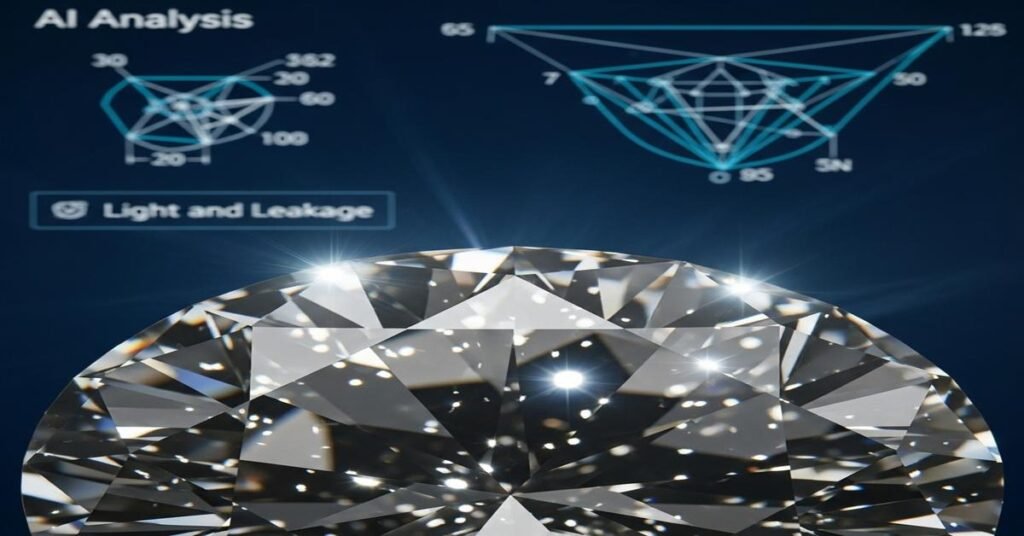

AI cut grading promises to see what your eye can’t. It uses photos, measurements and algorithms to score a diamond’s cut faster and cheaper than a human grader. That sounds useful. But there are real strengths and real limits. I’ll explain what AI can and cannot reliably tell you, why those differences matter, and how to use AI grading in practice.

How AI cut grading works

Most AI systems combine two inputs: precise geometric measurements and optical images. Measurements typically come from a scanner or sensor that records diameter, table size, crown height, pavilion depth, girdle thickness and symmetry down to fractions of a millimeter or to the nearest 0.01 mm. Images are taken under controlled lighting: darkfield, brightfield and oblique views. The software then uses pattern-recognition models — often convolutional neural networks — or physics-based ray-tracing to predict light behavior.

Why geometry matters

A diamond’s angles and proportions directly control how light is returned to the eye. Small changes in pavilion angle or crown angle change the path of light by degrees that matter. For example, a 1.00 ct round brilliant (about 6.50 mm diameter) with a table of 57%, crown angle ~34.5° and pavilion angle ~40.8° is likely to throw strong light back to the viewer. Shift the pavilion angle by 0.5° to 41.3° and more light can leak out the sides, reducing face-up brightness. AI can detect those angular differences precisely if the imaging and measurement hardware are accurate.

What AI sees better than the eye

- Microscopic geometry differences. AI picks up differences in angles and symmetry that are too small for unaided vision to quantify. That helps to screen for pavilion misangling, off-center tables or uneven girdles.

- Repeatability and objectivity. Machines apply the same criteria every time. Two human graders can disagree on a borderline cut grade. AI produces consistent outputs given the same inputs.

- Data integration. AI can combine hundreds of measurements plus image features to predict light return and scintillation metrics. Humans cannot track that many variables at once reliably.

- Speed and scale. For e-commerce or factory quality control, AI can grade thousands of stones per day. Humans cannot.

Where AI still struggles

- Training bias. AI is only as good as its training data. If the system was trained mostly on round brilliants, it will be less reliable on fancy shapes like pears or marquises, which have bow-ties and complex light patterns.

- Imaging limitations. Poor lighting, glare, reflections from the setting, or inconsistent camera angles will confuse the model. A reflection can look like an inclusion or a white facet. That’s why standardized imaging rigs matter.

- Human perception of beauty. Cut grade is a technical measure, but “beauty” is subjective. Two diamonds with the same light-return numbers can look different in person because of scintillation patterns, face-up size, or the way the wearer moves. AI cannot fully predict individual preference.

- Non-optical factors. Surface polish, minor facet junction issues, or internal graining affect appearance in subtle ways. Some of these are below the resolution of imaging sensors or are masked by reflections.

- Context and setting. A diamond mounted in a yellow gold bezel or worn with other stones changes perceived brightness. AI usually evaluates a loose stone, not a mounted one.

How labs and retailers use AI today

AI is commonly used as a first-pass tool. It pre-screens stones, flags outliers, and assigns preliminary cut scores. For stones that are expensive or near decision thresholds, human graders or full lab instruments do the final check. In production, manufacturers use AI to sort rough and finished goods by likely visual outcome, saving time and reducing waste.

What to ask for when you see an AI grade

- Ask for the raw measurements: diameter (mm), table (%), depth (%), crown height (mm or %), crown angle (°), pavilion angle (°). Numbers let you compare to known proportion sets (Tolkowsky, AGS ideals, etc.).

- Request ASET or Ideal-Scope imagery if available. Those images map light return and leakage directly. They show where the light is going, not just a single grade.

- Check whether the AI model was trained on round brilliants only or on a wider range of cuts. Fancy shapes need different training.

- Verify the hardware used for imaging: resolution (megapixels), lighting standardization, and sensor calibration matter. A scan that claims 0.01 mm precision should come from calibrated equipment.

- For high-value purchases (for many buyers that means multi-thousand-dollar stones), insist on an independent lab certificate in addition to any AI output.

Practical example

Imagine two 0.75 ct rounds, both ~5.8 mm across. Stone A has a table 56%, depth 61%, crown angle 34.2°, pavilion 40.9°. Stone B has a table 61%, depth 62.5%, crown 33.5°, pavilion 41.6°. An AI model trained on light-performance metrics can predict that Stone A will likely show stronger, evenly distributed light return and more pleasing contrast. A human might spot that Stone B looks brighter at first but shows uneven dark areas (extinction) when moved. The AI helps quantify the trade-off and shows which stone sacrifices balance for face-up brilliance.

Bottom line: use AI as a tool, not a verdict

AI cut grading is powerful for measurement, consistency and scale. It can reveal geometric issues invisible to the eye and speed up decisions. But it can be misled by poor imaging, limited training sets and the subjective nature of beauty. For routine purchases or screening, AI is very useful. For high-value stones or where appearance quirks matter — fancy cuts, mountings, or rare proportions — combine AI output with human inspection and standard lab reports. Ask for numeric data and light-mapping images. That way you get both machine precision and the human judgment needed to decide what actually looks best on the finger.

I am G S Sachin, a gemologist with a Diploma in Polished Diamond Grading from KGK Academy, Jaipur. I love writing about jewelry, gems, and diamonds, and I share simple, honest reviews and easy buying tips on JewellersReviews.com to help you choose pieces you’ll love with confidence.